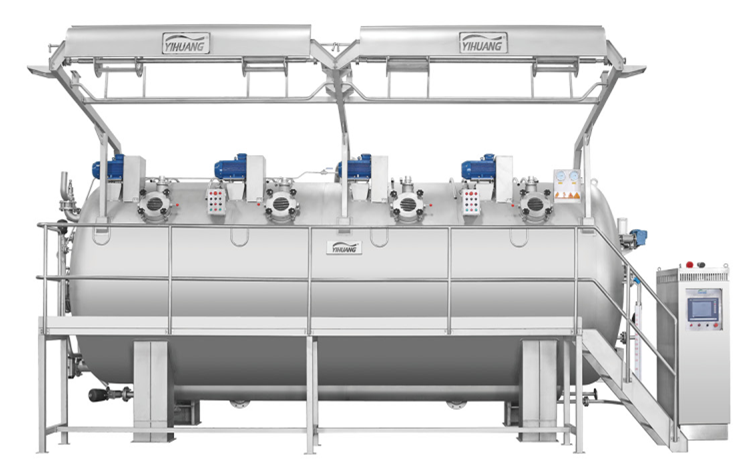

For the traditional airflow and air-liquid fabric dyeing machine, the electricity consumption is large and when dye the light weight fabric will not work well. And we have technical and design updates for the fabric guide tubes, nozzles, fabric chamber and adjustable boards of YOH-300A HT overflow fabric dyeing machines.

1. Each capacity is 300kg/tube and the electricity consumption is 0.016kw H/kg.

2. Cotton and polyester cotton liquor ratio is 1:4-1:5 at full load capacity and the fabric has a good levelness.

3. The turbulent dyeing guide tube effectively reduces the crease formed by repeated folding of the fabric during the rope dyeing process.

4. The high-pressure and large-flow circular nozzle has strong penetrating power and high exchange capacity, which effectively solves the problems of the nozzle is easily blocked and the differences in shades and tubes caused by high-speed double ropes dyeing.

5. Settling type fabric winch device, small tension and low running noise when dyeing.

ADD:Room 2317, Zhongxin Building, No.268, Baogang Avenue, Guangzhou, China

ADD:Room 2317, Zhongxin Building, No.268, Baogang Avenue, Guangzhou, China  TEL : 0086-20-34229974

TEL : 0086-20-34229974  E-Mail: eric@gzrunhao.net

E-Mail: eric@gzrunhao.net